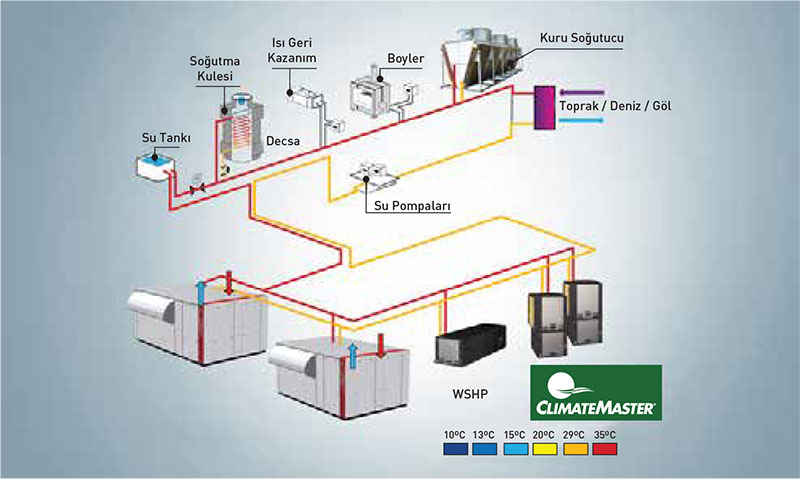

Boiler / Tower Systems

The greatest need of modern buildings is to be able to heat and cool in different sections at the same time throughout the year.

Today's well isolated; business center, shopping mall, hospital, hotel etc. In buildings, the need for heating and cooling often occurs together. This is due to both insulation and increased internal loads.

The water source heat pump loop line is closed circuit and the cycle water temperature is kept in the range of 15-30C all year round. This range may vary +/- a few degrees depending on the location of the project and wet bulb temperature.

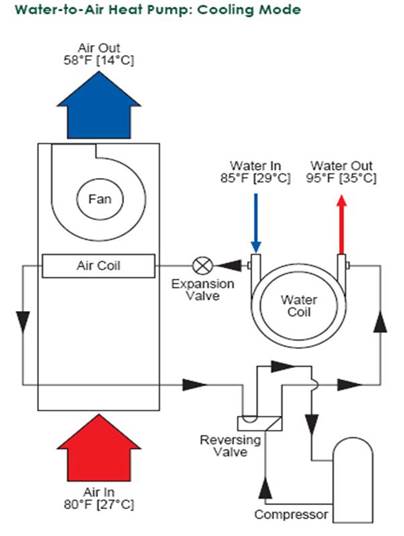

Cooling

The cooling tower is active, the boiler is off. WSHP units operate in cooling mode. Meanwhile, with the energy exchange in the condenser line, the inlet water is heated and transferred to the loop. ∆T = 5-6 oC. The tower steps in and out to catch the value it is set. (For example 30 / 35oC)

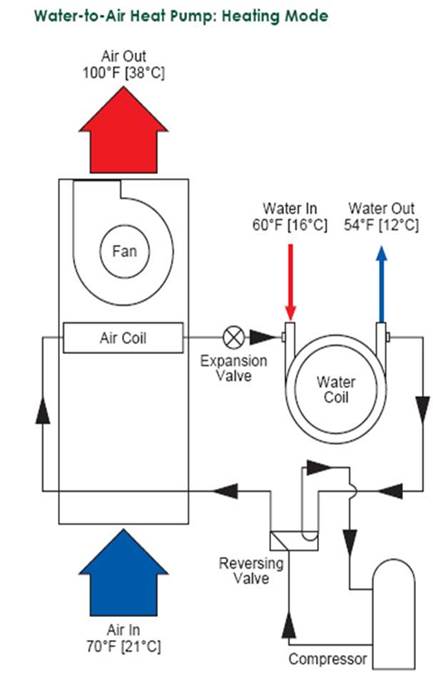

Heating

The boiler is active, the cooling tower is off. WSHP units operate in heating mode. Meanwhile, with the energy exchange in the condenser line, the inlet water is cooled and transferred to the loop. ∆T = 5-6oC. The boiler switches on and off to catch the set value. (For example 25 / 20oC)

Cooling and Heating (at the same time)

The boiler and cooling tower units are in off mode. WSHP units operate in heating and cooling mode. When cooling and heating are done at the same time, heat recovery occurs between units. Energy saving and high efficiency operation is provided. The loop line water temperature is kept in the range of 15 and 30oC

.

.

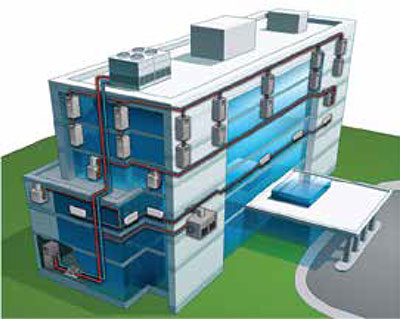

Boiler – Tower System

As the main equipment of the system; Cooling tower and boiler are used on the source side, and water-to-air heat pumps are used on the building / load side. A smaller capacity cooling tower and boiler are used compared to conventional systems.

It is especially preferred in Mall-Office and Shell & Core type commercial buildings. The system stands out with its high efficiency operation and low energy consumption thanks to heat recovery between units when heating and cooling are performed at the same time.

Water Source Heat Pump System Design

- Thanks to the increased internal loads and heat recovery, it has been observed that half of the total heating capacity is sufficient in many applications and boiler capacity is generally accepted as 40-50% of the total heating capacity.

- Water Loop line piping has 2 pipes and does not require insulation.

- Depending on the capacity of the unit, water flow rate in the condenser line is important. For this reason, connection kit with dynamic balancing valve is used in the piping of the installation side in heat pump systems. These kits are available as ready packs. If the circulation pumps in the system have VFD, a motorized valve in the kit should be used to save energy.

- Before the startup, flushing in the close loop line should be done.